The House of Industrialized Construction

Industrialized Construction (IC) spans both manufacturing and construction. With its foundation built with process and technology enablers, industrialized construction can reach beyond prefabrication and production. IC helps eliminate bottlenecks that come with transferring data from design to production. It is not only important to productivity but to the efficiency of both construction and manufacturing projects. Autodesk's technologies allow silos to be broken down and combined to make the transfer of data both easier and smarter, giving you access to data across your projects.

Learn about IC from the experts!

Hear from Autodesk experts Amy Marks and Ryan McMahon in this exclusive presentation from our event in Denver in August 2022. Fill out the form to access this content and unlock the full potential of Industrialized Construction.

What are the benefits?

IMPROVED PRODUCTIVITY AND ASSEMBLY PRECISION

Prefabrication can be less expensive than onsite construction, but the productivity benefits of data for manufacture and assembly (DfMA) go far beyond simple cost savings. By standardizing build components and simplifying assembly, projects can be erected by smaller teams. The repeatable nature of prefabrication allows builders to continuously improve equipment and processes that cannot be reproduced onsite. Frequent checks confirm strict adherence to specifications like cuts and connections being practiced and confirmed accurate. Assemblies that fail to meet specifications are corrected immediately, not found, and repaired later. The result is a consistent quality that’s reflected in the finished product.

REDUCED WASTE AND ENHANCED HEALTH & SAFETY

DfMA can reduce site waste by up to 90 percent through better materials in stock and ready to use. Any remnant materials are used where possible instead of being discarded as scrap. Whereas materials at job sites are subject to all sorts of weather, from rain and snow to damaging winds. We can reduce neighborhood pollution and congestion by up to 20 percent due to fewer traffic movements to and from building sites. Reduced need for onsite labor can lead to an 80 percent reduction in incidents.

SHIFT FROM A PROJECT MINDSET TO A PRODUCT MINDSET

Switching from building snowflakes to a product-led mindset increases standardization for BIM Protocols, Collaboration, Supply Chain Management, Onsite/Offsite Manufacturing, Quality, Delivery Logistics, Onsite Assemble, and Installation. This drives the Repeat, Re-purpose, and Recycle mindset for every project going forward, which then increases the Certainty and Productivity across the entire organization.

SPEND LESS TIME ON SHOP DRAWINGS AND MORE ON INNOVATION

In the construction industry are some of the world’s most creative minds. Too often, their creativity is wasted on solving procurement problems and overcoming logistical hurdles. By bringing a level of standardization to the manufacture, shipping, and assembly of built components, industrialized construction frees up those creative minds to move important initiatives. We need to stop the process where, at the end of a project, we see teams disband, and none of those learning gets retained and added to the next project.

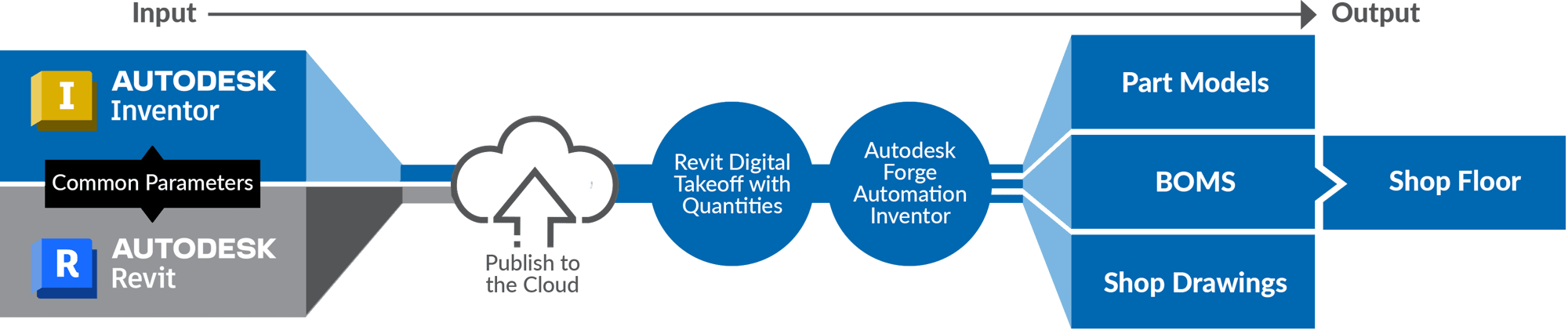

INDUSTRIAL CONSTRUCTION AUTOMATION

The key goal is "How do you automate processes and workflows of taking the critical design data that is in your Revit design files and auto-generate the necessary g-code for your automation machines on the shop floor?" One method is taking a robust parameter laced LOD 100 family in Revit and linking it to Inventor with iLogic rules, then using the Autodesk Forge platform to auto-generate the Inventor part models, bills of materials, shop drawings, and more. This method breaks down all the data silos, broken manual processes, and headaches that a lot of construction firms are experiencing today. This helps you start fabrication faster, reduce material waste, respond to bids faster, and spend less time manually producing your prefabrication outcomes.

BUILDING PRODUCT MANUFACTURES

Building Product Manufactures (BPM) are included in this industrial construction process and workflow. More and more BPMs have Revit content on their website so the AEC industry can download and spec their products on a project. The industrial construction workflow gives the BPMs a method to do digital takeoff’s directly from the Revit model into their Inventor manufacturing process and workflows. The same IC automation can be used to auto-generate the Inventor part models, bills of materials, shop drawings, and more.

DATA MANAGEMENT

Industrialized Construction allows you to organize disjointed data into manageable, connected data slices. Connecting information with data management creates visibility and predictability by creating one source of truth where the data can be accessed, automated, and consumed. Manufacturing has used this technology for years, and now the construction industry can take advantage of the same technology to organize their data.

AUTOMATION

Industrialized Construction allows you to automate your construction and manufacturing processes from prefabrication to production. Autodesk's tools allow you to partner with design for manufacturing and assembly experts to create a scalable product that is defined, managed, and optimized for a specific need. The resulting components can be incorporated during a structure’s design phase and then procured like equipment. With IC Automation, you can generate relevant data for AEC firms, reduce engineering time, automate workflows and improve project collaboration, and deliver on convergence.

Have questions?

Let us help you find the best solution for your team. Complete this form to have a sales expert contact you.