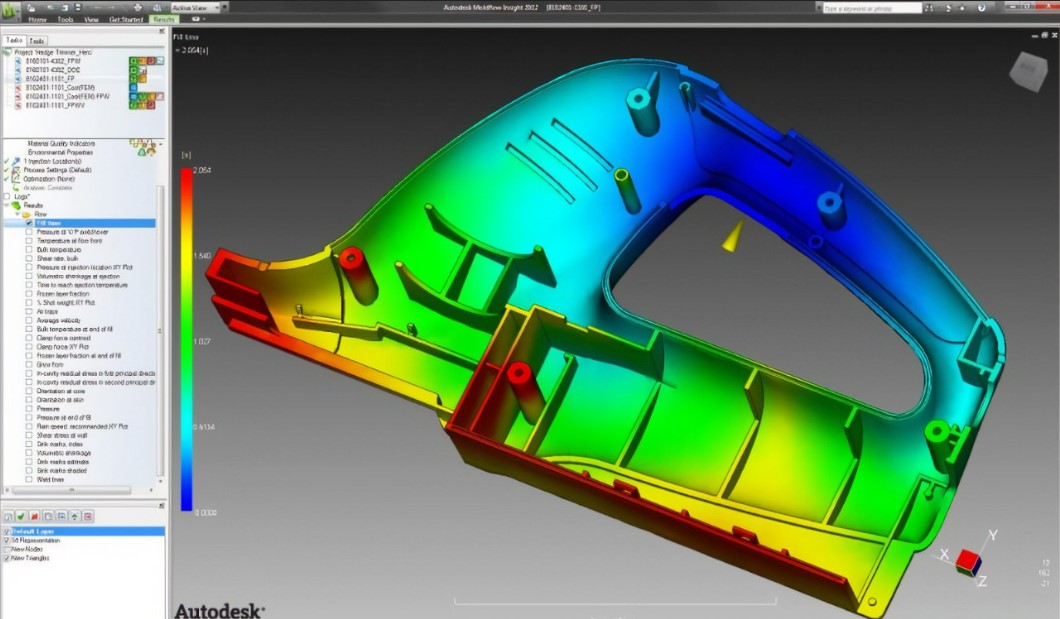

Moldflow

Key Moldflow Features

Moldflow® software helps reduce manufacturing defects through plastic injection molding simulation. Access tools for injection mold design, plastic part design, and mold processing.

Mesh to solve with one click

Improve your productivity by meshing and analyzing your model in one step.

Fusion 360 for CAD preparation

Moldflow includes Fusion 360 in-product push to help with quick CAD simplification and repair.

Collaborate using Shared Views

Collaborate using cloud-connected devices to share results, comment, and design recommendations.

Runner balancing

Runner balance analysis guides users in sizing multi-cavity runners for even pressure and fill time.

Mold cooling circuits

Automate cooling channel creation with a wizard, import from CAD curves, or manually draw circuits.

Defect visualization

Analyze part warpage and evaluate potential design flaws to improve part quality.

Flexible solving

Use the Simulation Compute Manager (SCM) to solve analyses locally, on a server, or on the cloud.

Chemical Foam Molding

Simulate foaming of thermoplastic and thermoset materials (including polyurethane).

Control valve gate opening/closing

Include controlled and sequential valve gates within simulations, along with hot runner layouts.

Predict shrinkage and warpage

Visualize part quality concerns to identify causes of warpage and apply shrink compensation factors.

Part and process optimization

Use automated design of experiments and parametric analysis to locate the best process and design.

Total coolant flow history

Run a coolant flow analysis to review coolant properties as it flows from the pump to the mold.